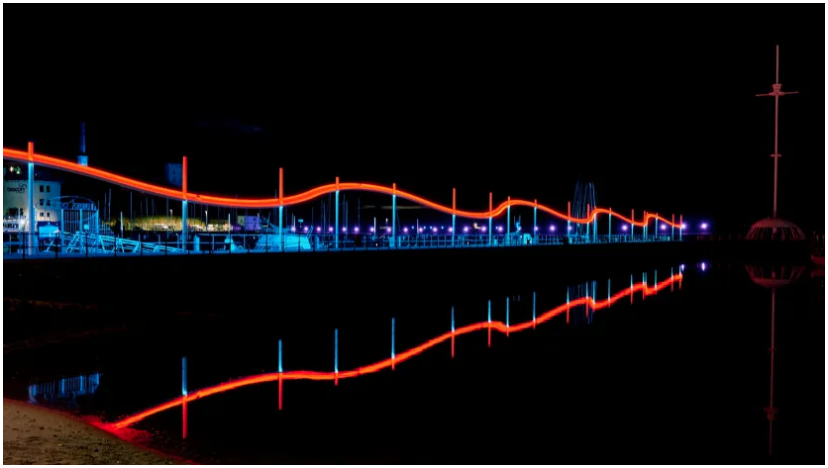

NIS were delighted to assist Whitehaven Harbour Commission (WHC) with their project “Relight the Wave”, which is a 200m art installation on Whitehaven Harbour.

Originally built as one of the nationwide Millennium Projects, the sculpture was just part of a multi-million-pound investment in Whitehavens Georgian Harbour and when lit it was a highly visible attraction often drawing visitors into the Town. However, wear and tear, and the vulnerabilities of the technology of the time meant the lighting couldn’t be sustained and it hasn’t been lit for a number of years.

WHC have been keen to find a way to reignite the wave and have worked with Forth Engineering who have found a way to do it in the most ecofriendly, low carbon way.

The lighting was designed and procured however as the installation date drew nearer it was recognized that the structure was in desperate need of cleaning, not only to get the best visual outcome but also to give the fitting team a better working environment, so 8 days before installation was due to begin a call for help was made to the PPP supply chain.

As a niche engineering company specializing in nuclear containments and fabrications, we often find it difficult to deploy our skill set within the local community. We therefore saw this project as a fantastic opportunity to pull a capable team together from our Chorley HQ and our sister company Hold Engineering who are based in Beckermet, and got cracking!

The scope of the task was to clean the Wave structure using pressurized water. We needed to hire elevated working platforms and pressure washers, produce Risk Assessments and Method Statements, and sort the logistics to release a team of qualified people from their day jobs and get them mobilized in Whitehaven ASAP.

Because of the tight turnaround we got the team and documentation in place before we knew exactly what equipment had been available for delivery so it was a little disappointing to find that only one pressure washer could be sourced meaning only one workface could be opened!

However, rather than send the unused workforce back we were able to offer their services to the WHC who were extremely grateful to put them to work refurbishing an office space in their facilities. This saw a team of 3, 2 of which were apprentices, spend 2 days stripping, filling, sanding and painting an area that had previously been water damaged. So two projects were successfully completed instead of one!